1.Understanding the Function and Importance of Casing Spools in Fluid Transmission

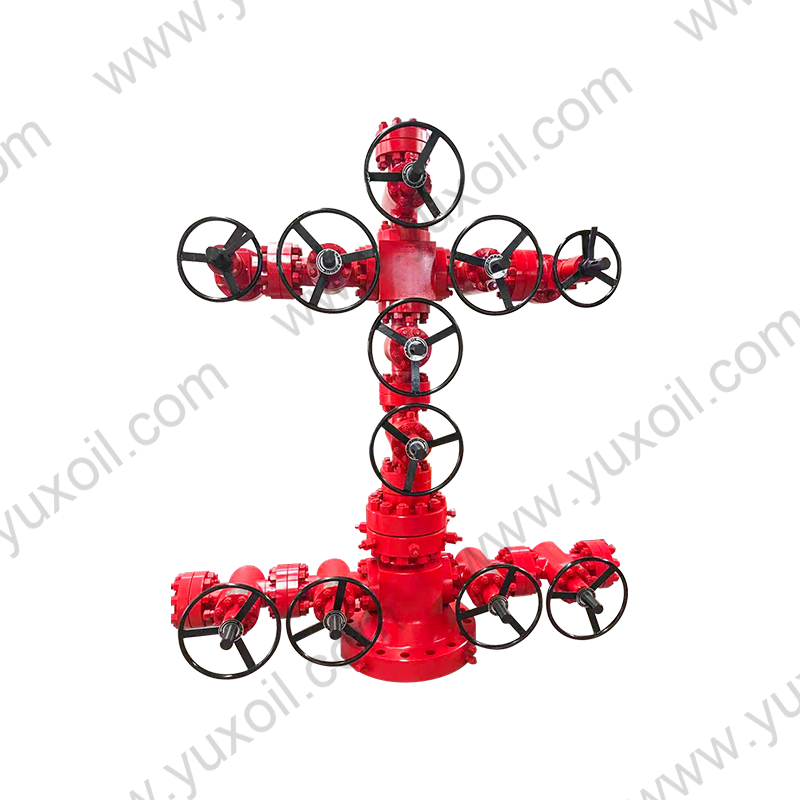

Casing spools are vital pipeline connection accessories, commonly used in industries such as petroleum, natural gas, and chemical processing, where the transportation of fluids under high pressure is a critical part of operations. At their core, casing spools serve as connectors that link multiple pipelines, typically forming a cross-shaped intersection. This design allows for the controlled flow of fluid in different directions, helping to efficiently manage the fluid distribution within complex pipeline networks.

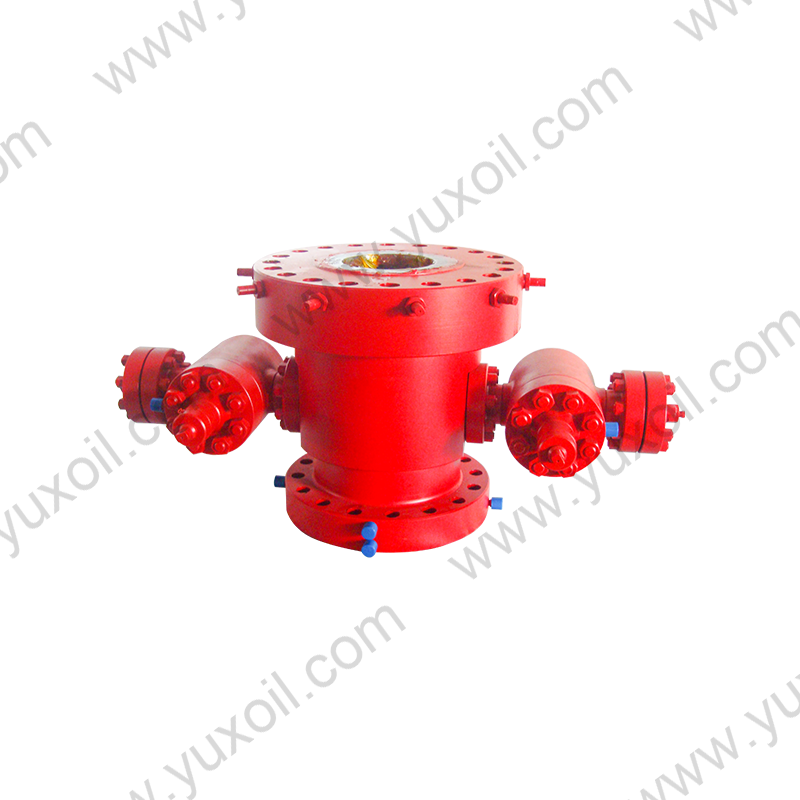

The main function of a casing spool is to ensure the stability and safety of the fluid flow, especially under high-pressure conditions. Given the nature of industries like oil and gas, where pipelines often carry hazardous or volatile substances, the integrity of the connections is paramount. Casing spools are designed to withstand not only high pressure but also temperature variations and potential mechanical stresses. They maintain the pipeline's integrity, even in challenging environments, ensuring that fluids are transported safely and without disruption.

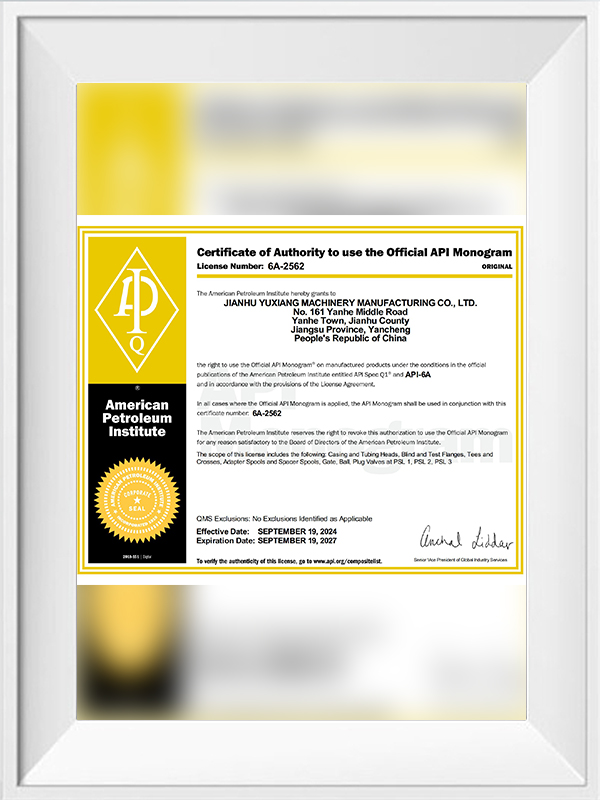

At Jianhu Yuxiang Machinery Manufacturing Co., Ltd., we understand the critical role casing spools play in the fluid transmission process. Our casing spools are engineered with precision to ensure reliable performance in the most demanding applications. By manufacturing casing spools that are capable of withstanding extreme pressures and temperatures, we provide essential solutions for industries that rely on safe and efficient fluid management systems.

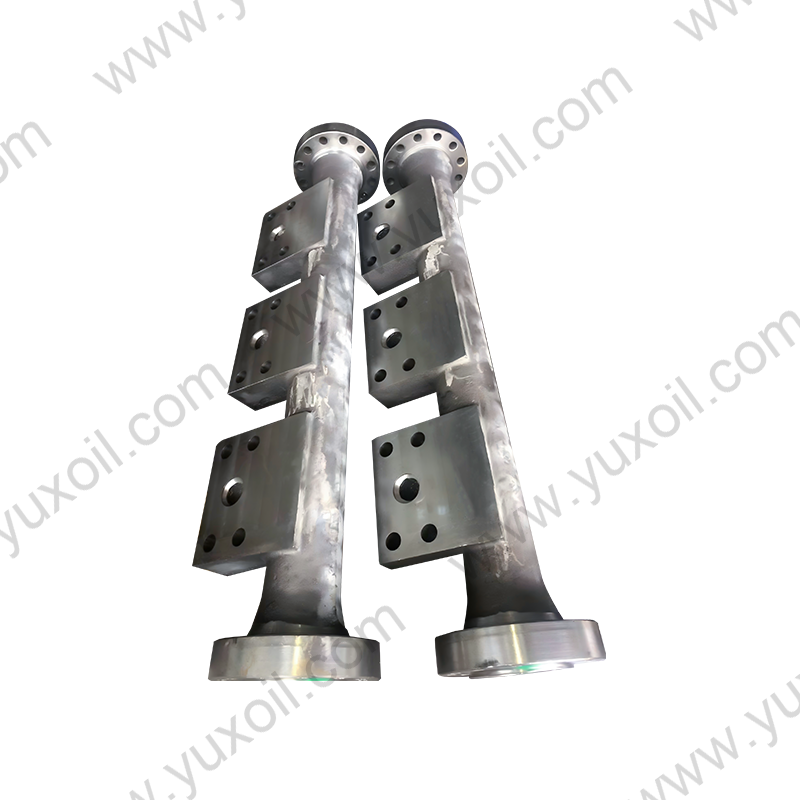

The construction of a casing spool is robust and features key components like flange connections and welding interfaces that allow for secure installation and provide leak-proof sealing. This design ensures that the casing spool can be seamlessly integrated into any pipeline system, whether it is for new installations or as part of routine maintenance or upgrades. The simplicity of the installation process, combined with the ease of maintenance, allows operators to ensure the continued operation of their pipeline systems without unnecessary downtime or complex procedures.

2.Key Features of Casing Spools: Durability, Sealing, and Ease of Maintenance

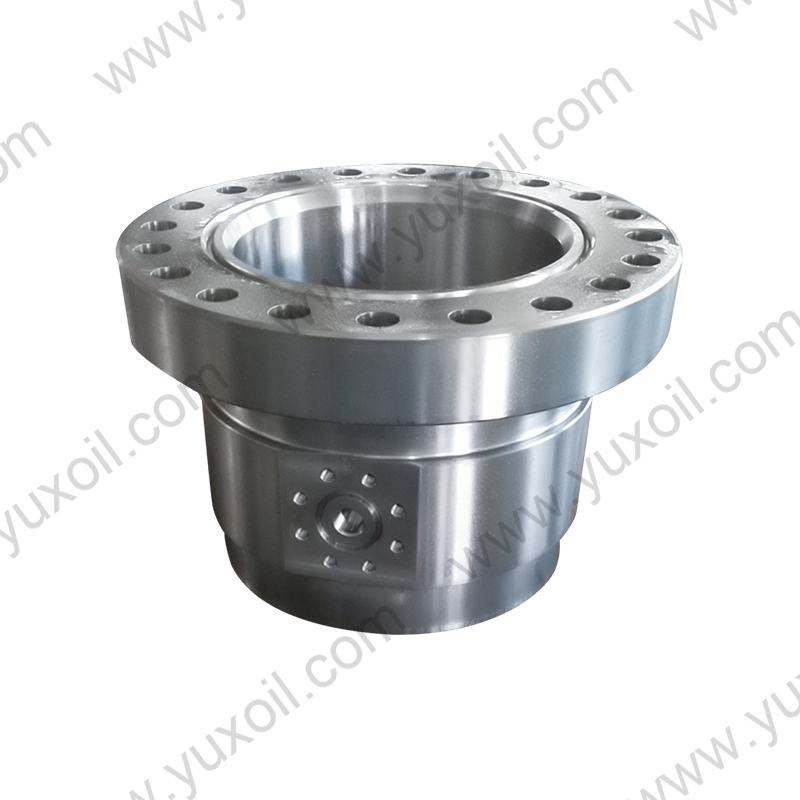

One of the most important features of casing spools is their durability. These components are made from high-quality, corrosion-resistant materials that are designed to withstand the rigorous demands of fluid transmission systems, particularly in industries like oil and gas. These industries often operate in environments where the spools are exposed to extreme temperatures, high pressures, and corrosive substances. Therefore, casing spools must be crafted from materials that offer excellent resistance to these conditions.

At Jianhu Yuxiang Machinery Manufacturing Co., Ltd., our casing spools are built to last. We use only the most durable materials, such as carbon steel, stainless steel, and other high-performance alloys, which offer superior resistance to corrosion, abrasion, and wear. This ensures that our casing spools maintain their structural integrity over time, even under the most challenging conditions. Our rigorous testing procedures ensure that each casing spool meets international quality standards, offering our clients long-lasting reliability in their fluid transportation systems.

In addition to durability, casing spools are designed to provide a tight seal to prevent leaks. Flange connections and welding interfaces play a crucial role in achieving this. The flange connections are designed to be bolted securely, providing a reliable, leak-proof seal that can withstand high-pressure fluid flow. On the other hand, welding interfaces offer additional strength and resistance to leakage, especially at critical junctions where the pipes meet. This combination of flange and welding technologies ensures that the casing spools maintain a secure, leak-free connection over time, even when exposed to high-pressure fluids.

The ease of installation and maintenance is another key feature of casing spools. At Jianhu Yuxiang Machinery Manufacturing Co., Ltd., we understand the importance of minimizing downtime in industrial operations. Therefore, our casing spools are designed to be easy to install, requiring minimal effort from technicians. Their user-friendly design also facilitates routine maintenance, which helps extend the life of the spool and ensure the continued efficiency of the pipeline system. With simple replacement or repair procedures, operators can easily maintain the integrity of their pipeline network.

3.Applications of Casing Spools Across Various Industries

Casing spools are essential in a variety of industries where fluid transmission is a fundamental part of operations. In the petroleum and natural gas industries, casing spools are crucial for connecting pipelines and directing the flow of fluids from the wellhead to processing plants or storage facilities. These industries require highly reliable pipeline components to ensure the safety of operations, especially when dealing with volatile substances like crude oil, natural gas, or refined petroleum products. Casing spools facilitate the safe and controlled movement of these fluids, even under extreme pressure conditions.

In the oil fields, casing spools are used to manage the flow of oil and gas as they are extracted from the earth. These components provide the necessary connections between the drilling equipment and the surface pipeline systems, ensuring that fluids can be transported without leaks or interruptions. Similarly, in gas fields, casing spools are used to connect pipelines that carry natural gas from extraction points to processing facilities or distribution networks. Their ability to handle high-pressure gas flow makes them an indispensable part of the infrastructure in gas production systems.

Chemical plants also rely on casing spools to manage the flow of various chemicals and liquids within the plant. Given the often corrosive nature of the substances processed in chemical plants, casing spools must be designed with materials that can withstand chemical exposure while maintaining a reliable seal. Casing spools ensure the safe transportation of these fluids through the plant, preventing spills, leaks, or contamination.

At Jianhu Yuxiang Machinery Manufacturing Co., Ltd., we understand the diverse needs of these industries and the critical role that casing spools play in fluid management. Our products are designed to meet the specific requirements of oil fields, gas fields, and chemical plants, ensuring that fluid transmission is safe, efficient, and reliable. Whether it’s for high-pressure gas flow, crude oil transport, or the handling of chemicals, our casing spools provide the necessary strength, sealing, and ease of maintenance that these industries demand.

Casing spools are also used in a variety of other sectors, such as power plants, water treatment facilities, and even marine applications. In all these cases, the primary function of casing spools remains the same: to ensure the safe and efficient flow of fluids through a network of interconnected pipelines. As such, casing spools play a crucial role in the smooth operation of many different industries, supporting fluid transportation and management systems that are vital to modern infrastructure.

English

English русский

русский Español

Español