1. What Are Discharge Air Bags and Their Role in Casting and Forging Industries?

Discharge air bags are critical components in the manufacturing and processing of castings and forgings, particularly in industries where precision, durability, and reliability are paramount. These air bags are specifically designed to manage the flow of various substances used in industrial operations, including drilling mud, cement slurry, clay glue, and mortar. In casting and forging operations, such as those utilized in the oil and gas industry, discharge air bags ensure that the medium flows smoothly and efficiently, preventing clogs or malfunctions that could lead to delays and increased operational costs.

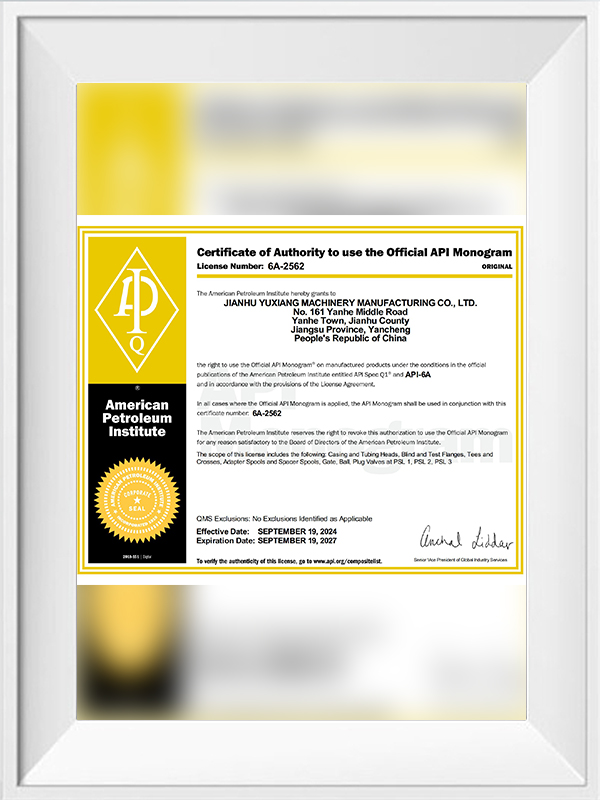

At Jianhu Yuxiang Machinery Manufacturing Co., Ltd., we understand the importance of these components in the overall performance of mud pumps, such as the BOMCO models F500, F800, F1000, F1300, F1600, F1600HL, and F2200HL. These mud pumps are widely used in various industrial applications, including well drilling, cementing, and well repair, which require the precise and stable delivery of drilling fluids to facilitate smooth operation. Discharge air bags play a vital role in this process, ensuring the reliable transportation of viscous media, under high pressure, to support these complex operations.

For companies like Jianhu Yuxiang Machinery Manufacturing Co., Ltd., ensuring the quality and durability of discharge air bags is essential. These components must be designed to withstand high pressures, extreme temperatures, and harsh operating conditions. A high-quality air bag prevents leaks, blockages, or ruptures, allowing the entire system to run smoothly and efficiently. Moreover, these air bags are typically customized to meet the specific requirements of each industrial sector, whether it be oil and gas, construction, or mining. In industries such as coalbed methane extraction or geothermal well drilling, air bags ensure that fluid delivery remains consistent and uninterrupted, even in the most challenging environments.

2. How Discharge Air Bags Enhance Operational Efficiency in the Oil & Gas Industry

The oil and gas industry relies heavily on the seamless operation of a wide variety of equipment, from pumps to air bags, in order to facilitate complex tasks such as drilling, cementing, and well repair. Discharge air bags play a crucial role in optimizing the performance of these operations. These air bags ensure the smooth and consistent delivery of drilling fluids, such as mud and cement slurry, which are essential for the drilling process. By stabilizing the fluid flow and managing the pressure within the system, discharge air bags help prevent downtime and equipment failure, ultimately improving operational efficiency.

In particular, when paired with BOMCO mud pumps—such as the F500, F800, F1000, F1300, F1600, F1600HL, and F2200HL models—discharge air bags can help improve the stability and performance of the entire system. Jianhu Yuxiang Machinery Manufacturing Co., Ltd. produces high-quality discharge air bags specifically designed to optimize these mud pump models. The consistent performance of these components ensures that drilling, well cementing, and repair operations can be carried out without unnecessary interruptions. The air bags not only regulate the flow of viscous media but also absorb any shocks or fluctuations that might otherwise cause damage to the pump system.

One of the primary advantages of using discharge air bags in the oil and gas industry is their ability to transport fluids efficiently under high pressure. Whether drilling for water wells, geothermal wells, or exploring coalbed methane and shale gas, the stability provided by discharge air bags is crucial for maintaining consistent pressure and flow. Without them, the risk of blockages, leaks, or pressure drops increases significantly, leading to costly delays and repairs.

The design of these air bags has evolved to offer superior durability and resistance to extreme environmental conditions. In applications such as coalfield exploration and frozen well operations, where temperatures can drop significantly or where debris may obstruct the flow of media, discharge air bags are engineered to withstand these challenges, providing reliable and consistent service. Jianhu Yuxiang Machinery Manufacturing Co., Ltd. has ensured that our air bags are built to meet these rigorous demands, contributing to more reliable and cost-effective operations in the oil and gas sector.

3. The Importance of Design and Durability in Discharge Air Bags for Industrial Operations

The design and durability of discharge air bags are pivotal in ensuring their reliability and efficiency across various industrial operations. These components are subject to extreme conditions, such as high-pressure environments, harsh temperatures, and exposure to abrasive materials. As a result, the design process for discharge air bags must prioritize not only flexibility and functionality but also strength and resistance to wear and tear. At Jianhu Yuxiang Machinery Manufacturing Co., Ltd., we understand that the longevity of these components directly impacts the overall performance and stability of the entire system.

Discharge air bags are engineered to withstand the stress and demands of heavy-duty industrial operations. Their primary function is to ensure the stable transport of fluids, such as drilling mud and cement slurry, without interruption. To achieve this, air bags must be designed with materials that are resistant to corrosion, abrasion, and extreme pressure. If the design and construction are not up to standard, the air bag can fail, causing fluid loss, equipment damage, or costly downtime. This is why Jianhu Yuxiang Machinery Manufacturing Co., Ltd. invests heavily in research and development to ensure that our air bags are made from high-quality, durable materials and are crafted to meet the highest industry standards.

One of the key factors in the durability of discharge air bags is the precision of their manufacturing. These components must be made with meticulous attention to detail, as even the slightest flaw in design or construction can lead to malfunction or failure. At Jianhu Yuxiang Machinery Manufacturing Co., Ltd., we use state-of-the-art equipment and rigorous quality control measures to ensure that each air bag we produce is free from defects and meets the performance standards required for the demanding applications of the oil and gas, mining, and construction industries.

The durability of discharge air bags is also influenced by their ability to withstand environmental stresses. For example, in coalfield exploration, where temperatures can fluctuate drastically, or in frozen well operations, where harsh environmental conditions are prevalent, the air bags must continue to function reliably. A well-designed air bag from Jianhu Yuxiang Machinery Manufacturing Co., Ltd. will not only perform effectively under these conditions but also extend the lifespan of the entire mud pump system. This minimizes the need for frequent maintenance and replacement, ultimately lowering operational costs and increasing system reliability.

English

English русский

русский Español

Español