1.What is the Purpose of Cross Over Spools in Oil and Gas Operations?

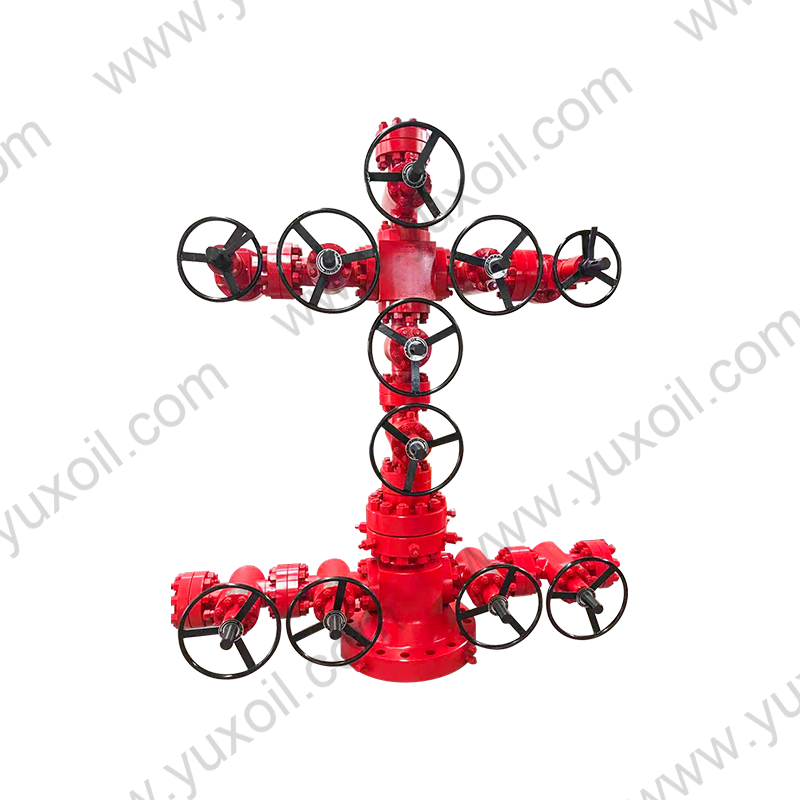

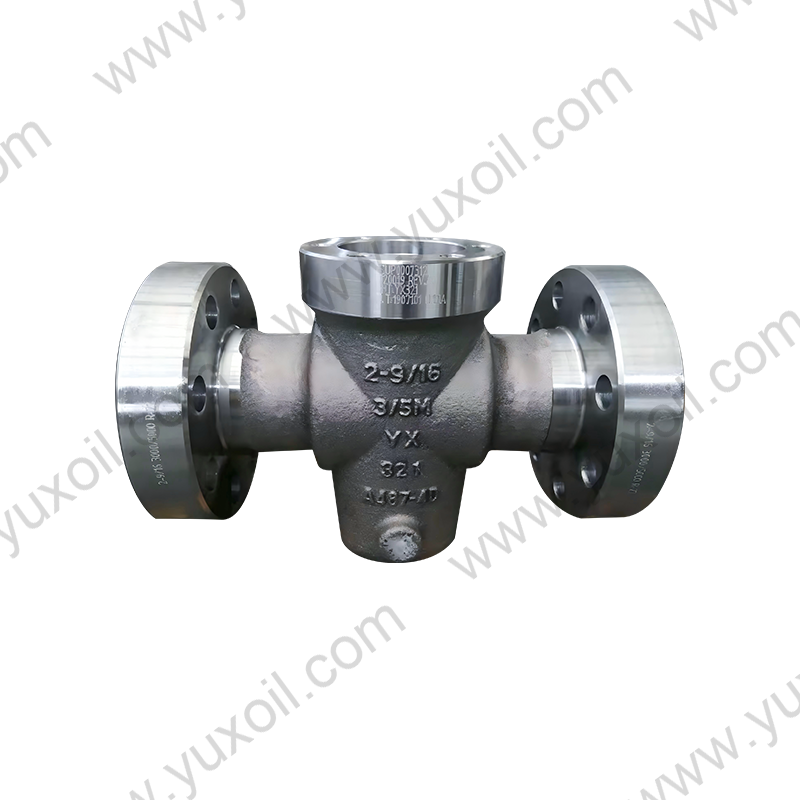

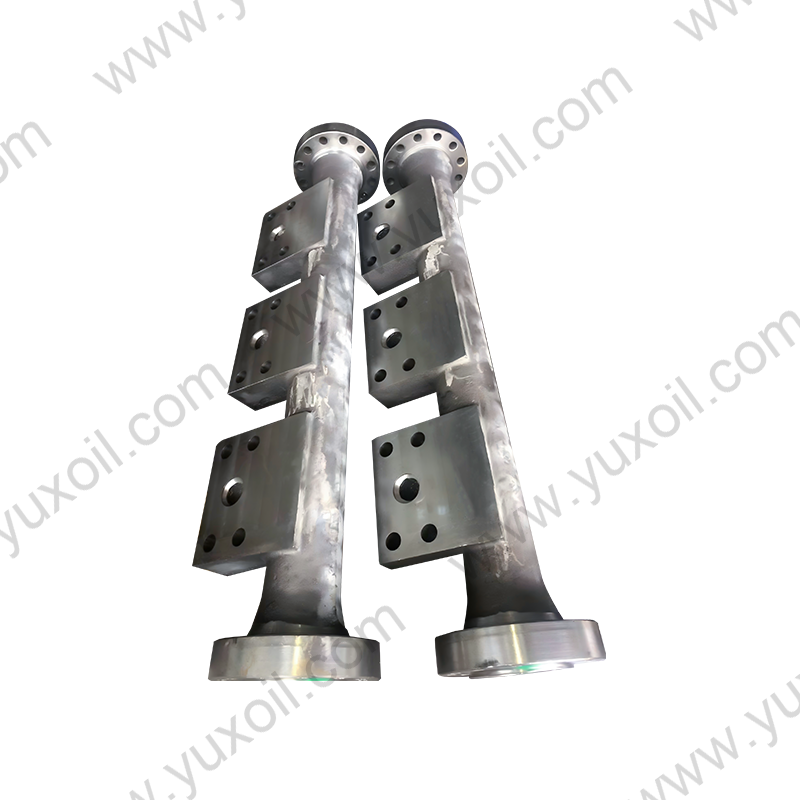

Cross over spools play a vital role in oil and gas operations, specifically in wellhead and Christmas tree systems. These components are designed to create secure, reliable connections between different pieces of flanged equipment, often with varying flange sizes and pressure ratings. Their primary purpose is to facilitate the seamless transfer of fluids, gases, or other materials through a system, ensuring that the connection is not only effective but also safe under high-pressure and high-temperature conditions.

In the context of the oil and gas industry, operations such as drilling, production, and well completion require systems that can withstand the harshest environments, often in remote locations. Cross over spools are crucial in these settings because they provide the flexibility to connect various equipment, such as valves, pressure control equipment, and other vital components, each of which may have different specifications. For instance, when different flange sizes are used for various equipment across the system, cross over spools bridge the gap, ensuring a secure and leak-free connection. These spools are essential for maintaining the integrity of the system, particularly when different equipment needs to be integrated, enabling smooth operations without compromising safety.

Jianhu Yuxiang Machinery Manufacturing Co., Ltd. specializes in providing high-quality cross over spools that cater to the diverse needs of the oil and gas industry. By offering a wide range of flange sizes and pressure ratings, the company ensures that operators can find the exact component they need for their specific application. These spools are designed to handle pressure levels ranging from low to ultra-high, ensuring that they perform reliably under the most demanding conditions, whether in offshore, onshore, or subsea environments. In high-stakes industries such as oil and gas, where safety and operational continuity are paramount, having access to high-quality, well-engineered components like cross over spools is critical for achieving long-term operational success.

2.Why Are Cross Over Spools Ideal for Harsh Environments?

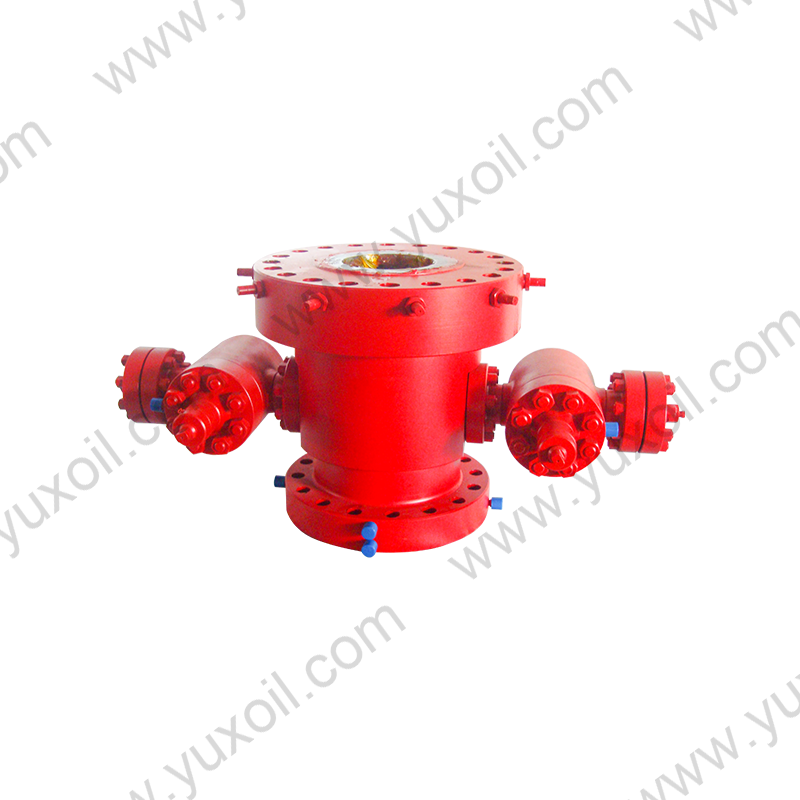

Oil and gas operations are often conducted in some of the world’s most challenging environments—subsea drilling, offshore rigs, high-altitude locations, and extreme desert climates. In such conditions, the reliability of each component used in the equipment is crucial to maintaining safe and efficient operations. Cross over spools, such as those offered by Jianhu Yuxiang Machinery Manufacturing Co., Ltd., are specifically engineered to endure these extreme environments.

The key to the performance of cross over spools in harsh conditions lies in their construction and material selection. These spools are made from high-strength, corrosion-resistant materials, which are necessary to withstand the intense pressure, temperature fluctuations, and corrosive substances commonly encountered in the oil and gas industry. For instance, the spools used in subsea or offshore operations are exposed to saltwater, which can cause severe corrosion over time. Without proper corrosion resistance, the structural integrity of the spools could fail, potentially leading to leaks or system failure. By using materials such as stainless steel, alloy steel, or high-performance alloys, Jianhu Yuxiang ensures that the cross over spools they provide are able to resist corrosion and maintain structural integrity in such environments.

These spools are designed to handle high-pressure systems, which are common in deepwater drilling or high-temperature applications. In these systems, the pressure can exceed several thousand psi, and if the spools are not made to withstand these pressures, they could fail, leading to dangerous situations. Jianhu Yuxiang's cross over spools are built to endure ultra-high-pressure environments, ensuring that the connection between equipment remains intact and operational under such extreme conditions.

The durability and corrosion resistance of these spools ensure long-term reliability and stability, reducing the need for frequent maintenance or replacements, which can be both costly and time-consuming in remote operations. With the high strength and resistance to extreme conditions, Jianhu Yuxiang’s cross over spools ensure safe, efficient, and uninterrupted operations, even in the harshest of environments.

3.How Do Jianhu Yuxiang’s Cross Over Spools Ensure Compliance with Industry Standards?

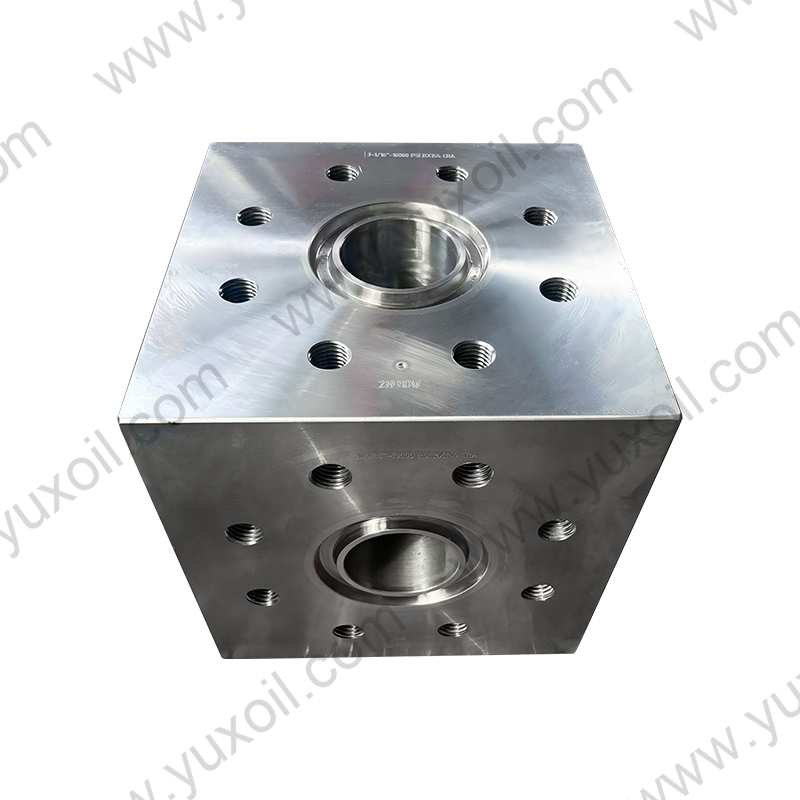

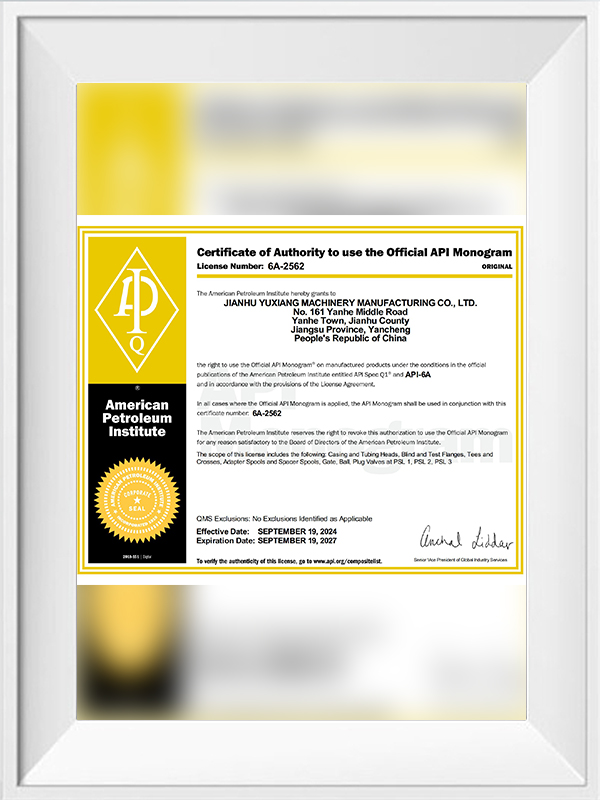

Ensuring that equipment meets or exceeds industry standards is a critical factor in the success and safety of oil and gas operations. This is particularly true for components like cross over spools, which must operate under extreme pressure and temperature conditions. Jianhu Yuxiang Machinery Manufacturing Co., Ltd. places a strong emphasis on compliance with international standards, such as the API 6A specifications, to ensure the highest levels of quality, safety, and performance.

API 6A is the recognized standard for wellhead and Christmas tree equipment, which includes pressure control equipment, valves, and associated components. Compliance with this standard guarantees that the cross over spools produced by Jianhu Yuxiang meet the necessary requirements for use in high-pressure and high-temperature environments, ensuring that they are safe for use in critical applications. The company's spools are designed and manufactured to meet these strict guidelines, giving operators the confidence that they are working with components that will function as expected, even in the most demanding conditions.

To maintain compliance with these rigorous standards, Jianhu Yuxiang subjects all of their cross over spools to a series of strict quality control tests. These include pressure tests, material integrity inspections, dimensional checks, and corrosion resistance assessments. By adhering to such stringent testing procedures, the company ensures that each spool performs at its best and that there are no compromises in quality. This quality assurance process is essential for preventing failure during operations, as even minor defects can result in significant safety risks and operational downtime.

English

English русский

русский Español

Español