1.What are Tubing Heads and Casing Spools, and Why Are They Important in Wellhead Equipment?

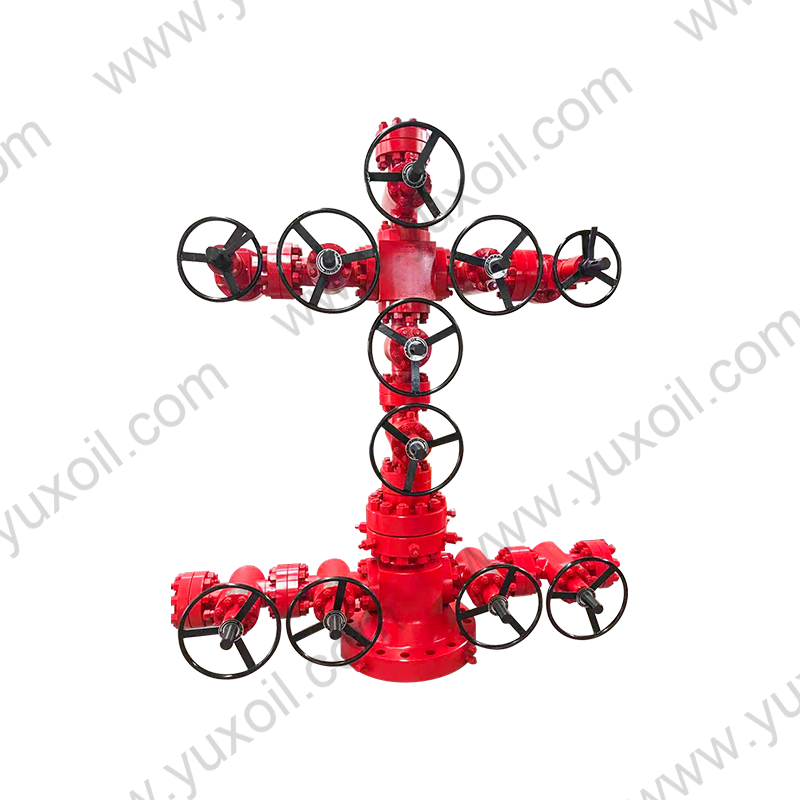

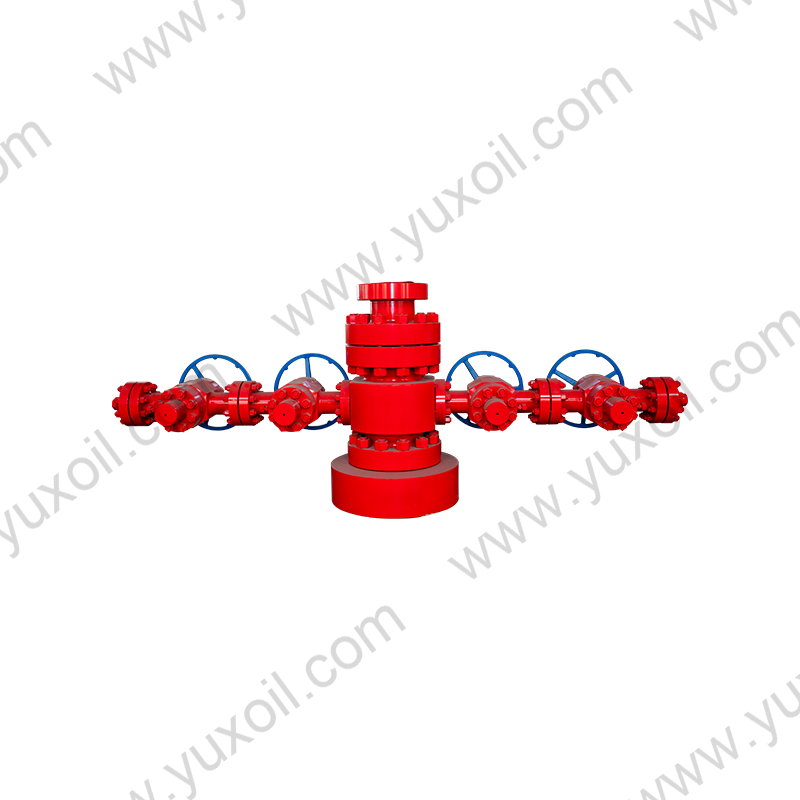

Tubing heads and casing spools are essential components in the wellhead equipment used for oil and gas production. These devices play a crucial role in the operation, control, and safety of wellbore systems. The casing spool serves as the primary connection point between the wellbore and the surface production equipment, while the tubing head provides a secure, pressure-tight connection for the tubing string, which allows for the production of oil, gas, or other fluids from the reservoir.

The casing spool is typically installed on top of the wellhead after the casing string has been cemented in place. It provides a connection for the blowout preventer (BOP) system and other equipment, ensuring the integrity of the well under high pressure and preventing the leakage of reservoir fluids. The casing spool can be equipped with various outlets for flowlines, gauges, and valves that allow operators to monitor and control the well's production.

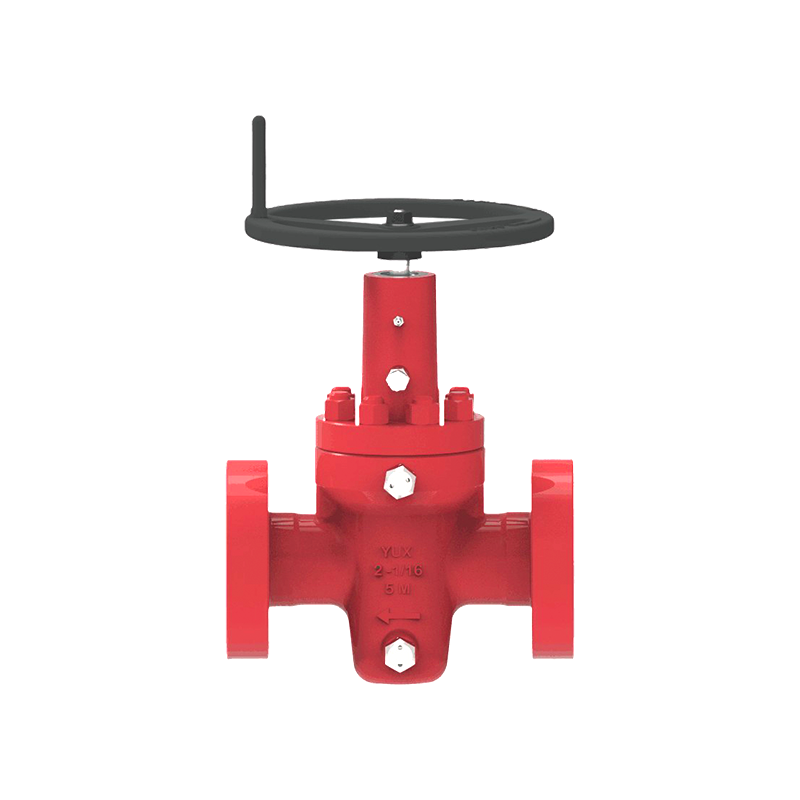

On the other hand, the tubing head is installed above the casing spool and is used to support the tubing string that runs down into the wellbore. The tubing head serves as a termination point for the tubing, where it connects to other production or injection systems. The tubing head provides a vital seal to contain the pressure inside the tubing and prevents any leakage to the surrounding environment. It is also equipped with outlets for control lines and other systems that allow operators to regulate the pressure and flow from the well.

Both tubing heads and casing spools are critical for maintaining the safety, efficiency, and performance of the wellhead equipment. Without these components, it would be impossible to manage the high pressures and complexities associated with deep well drilling and production.

2.How Do Tubing Heads and Casing Spools Ensure Safety and Pressure Control in High-Pressure Environments?

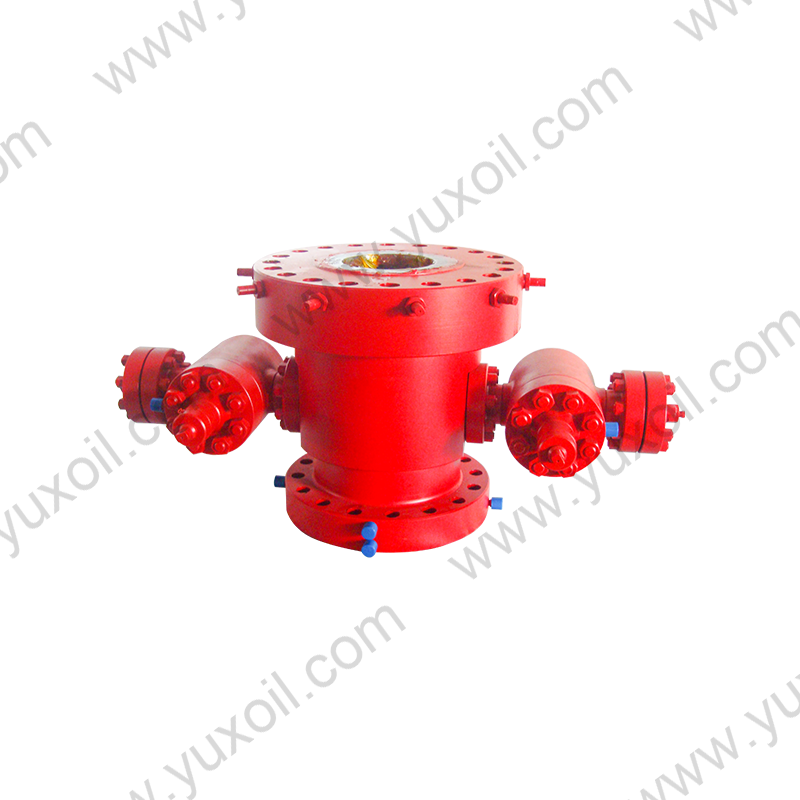

In the oil and gas industry, wellbore pressure management is paramount to ensuring safe operations. Tubing heads and casing spools are designed to withstand extremely high pressures and prevent blowouts, leaks, or other catastrophic failures. Their primary function is to maintain a sealed, controlled environment within the wellhead system, particularly in high-pressure environments such as deepwater drilling or high-temperature reservoirs.

The casing spool is usually the first line of defense in pressure control. It provides the interface between the wellhead and the blowout preventer (BOP) system, which is used to shut off the flow of oil or gas in the event of an emergency. The casing spool is designed to withstand the immense pressure exerted by the reservoir, especially during drilling, completion, and production phases. With a variety of pressure ratings available, casing spools can be customized to suit the specific needs of different wellhead systems, whether for shallow, deep, or ultra-deepwater wells.

Similarly, tubing heads are designed to provide a pressure-tight seal around the tubing string. They support the tubing under high-pressure conditions, preventing the release of fluids or gases from the well into the environment. Tubing heads also allow for the connection of additional pressure control equipment, such as pressure gauges, safety valves, and flow control systems. These components work together to regulate the flow of materials and fluids from the well and ensure that the wellhead remains stable even in extreme conditions.

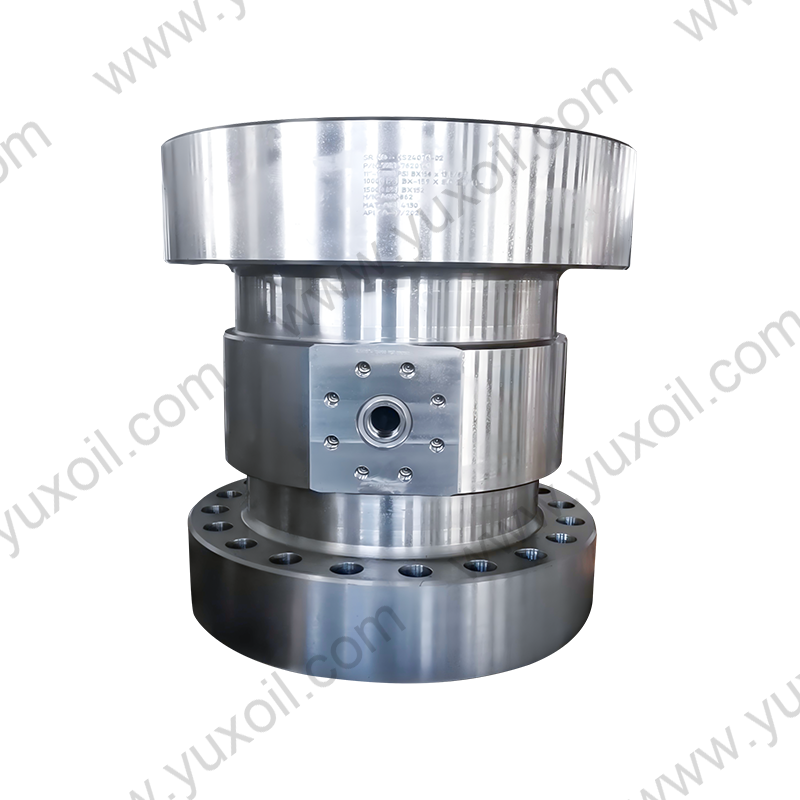

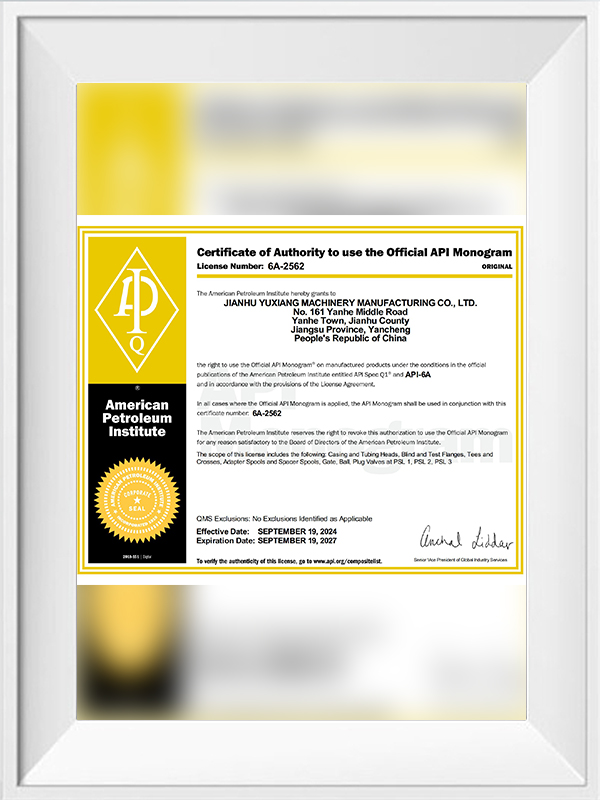

Manufacturers like Jianhu Yuxiang Machinery Manufacturing Co., Ltd. specialize in producing high-quality tubing heads and casing spools that meet international industry standards, such as API 6A and other pressure control specifications. By using high-strength alloys and corrosion-resistant materials, these components are able to perform reliably under the most demanding conditions. The careful selection of materials ensures that both tubing heads and casing spools maintain their integrity over the life of the well, even in harsh environments like deepwater oil fields or high-pressure onshore operations.

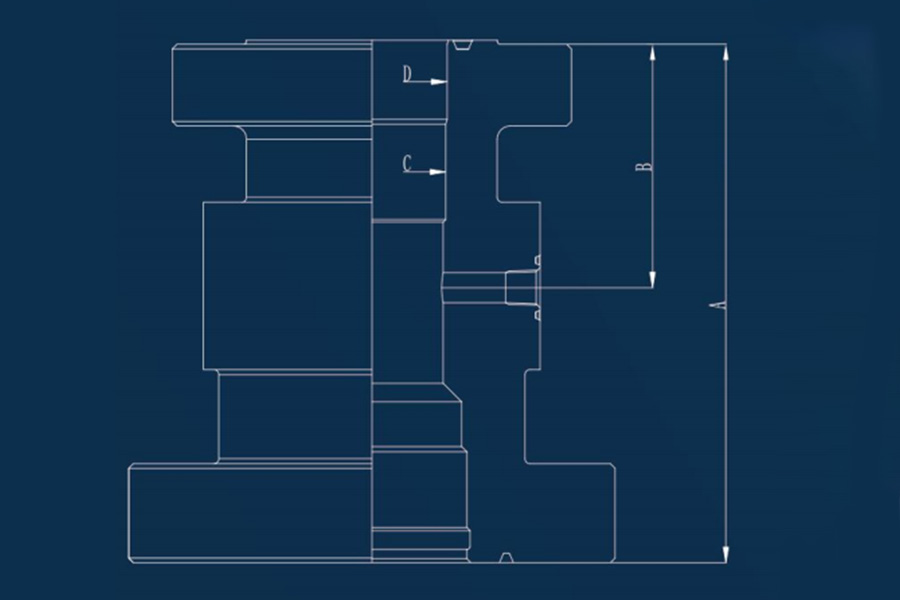

When selecting tubing heads and casing spools for an oil or gas operation, it is essential to consider a number of factors to ensure that the equipment meets the specific demands of the well and the environment. The choice of materials, pressure ratings, and design features plays a critical role in the performance and reliability of the wellhead system.

One of the key considerations is the pressure rating of the tubing head or casing spool. Depending on the depth of the well and the expected reservoir pressure, the equipment must be rated to handle the pressures that will be encountered. Manufacturers such as Jianhu Yuxiang Machinery Manufacturing Co., Ltd. offer tubing heads and casing spools with a range of pressure ratings, from standard pressure to ultra-high-pressure ratings, ensuring that operators can select the appropriate component for their specific application.

Material selection is also crucial for the longevity and durability of tubing heads and casing spools. These components are exposed to high temperatures, corrosive substances, and mechanical stress. As such, high-strength alloys, stainless steel, and corrosion-resistant materials are commonly used in their construction. These materials ensure that the components will withstand the harsh conditions of oil and gas reservoirs, whether in offshore, onshore, or subsea operations. The corrosion resistance of the materials used in tubing heads and casing spools helps to prevent wear and degradation over time, thus extending the operational life of the equipment and minimizing the need for costly maintenance or replacements.

The design features of tubing heads and casing spools should include easy installation and maintenance capabilities. Features like pressure-tight seals, multiple outlet connections, and standardized bolt patterns ensure that the components can be quickly and efficiently integrated into the wellhead system, reducing downtime and improving operational efficiency. These features also facilitate ease of maintenance, allowing operators to make repairs or replacements as needed without interrupting production.

It's important to ensure that the tubing heads and casing spools are manufactured according to industry standards, such as API 6A, to ensure that they meet safety and performance requirements. Manufacturers like Jianhu Yuxiang Machinery Manufacturing Co., Ltd. provide certified products that comply with these standards, offering reliability and assurance that the components will function as intended under high-pressure, high-temperature conditions.

English

English русский

русский Español

Español